RoboDK: Revolutionizing Industrial Robot Simulation and Programming

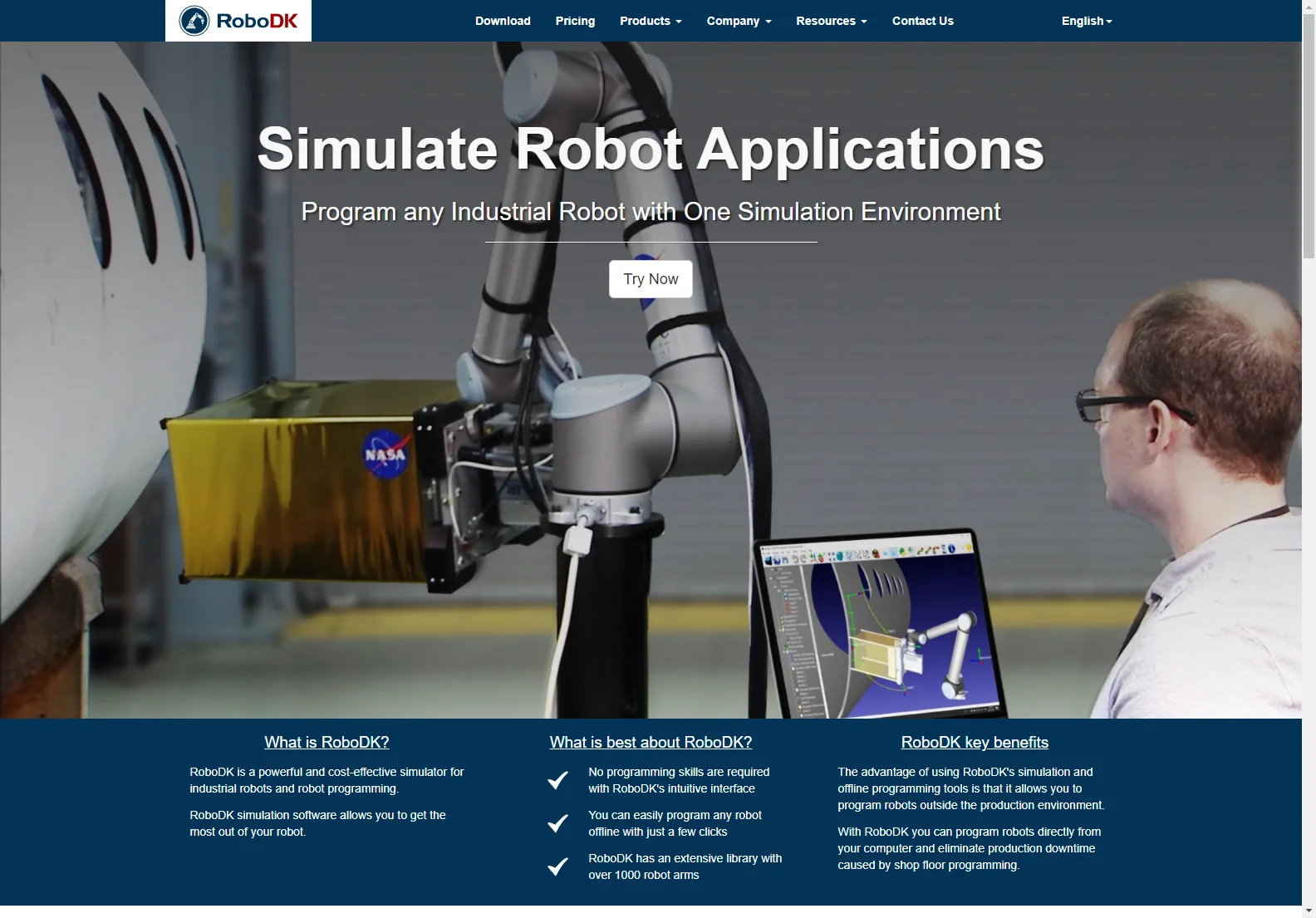

RoboDK is a game-changer in the world of industrial robotics. It offers a powerful and cost-effective simulator that allows users to get the most out of their robots.

Overview

With RoboDK, you don't need advanced programming skills. Its intuitive interface makes it accessible to users of all levels. The software enables you to program any robot offline with just a few clicks, saving time and increasing efficiency.

Core Features

One of the standout features of RoboDK is its extensive library of over 1000 robot arms. This allows for easy use of any robot for a wide range of applications, from machining and welding to cutting and painting. The simulation software also automatically optimizes the robot path, avoiding singularities, axis limits, and collisions.

In addition, RoboDK allows you to use your robot arm like a 5-axis milling machine or a 3D printer. It can simulate and convert NC programs to robot programs, opening up new possibilities for manufacturing.

Basic Usage

Creating a virtual environment to simulate your application is quick and easy with RoboDK. You can generate robot programs offline for any robot controller, eliminating the need to learn vendor-specific programming.

RoboDK also offers the ability to calibrate your robot arm to improve accuracy and production results. And with support for many robot controllers, exporting programs to your robot is a seamless process.

Whether you're a large company or a startup, RoboDK has proven to be a reliable software technology trusted by over 50,000 users in 50 countries.

In conclusion, RoboDK is a must-have tool for anyone working with industrial robots, offering a comprehensive solution for simulation and offline programming.